Liquid plastic roofing is gaining popularity as a flexible, durable solution for waterproofing both commercial and residential roofs. It offers a seamless, protective layer that adapts well to flat roofs, roofs with complex shapes, and areas that require strong waterproofing. At Surrey Roofing Specialists, we’ve seen the impressive performance of liquid plastic roofing for properties across the UK, and we specialize in this advanced solution for its longevity and resilience. This blog will guide you through the key aspects of liquid plastic roofing, including its benefits, applications, and installation process, so you can make an informed decision about upgrading your roof.

Liquid plastic roofing is a form of roof coating made from durable, weather-resistant materials that are applied in liquid form. Once applied, the liquid plastic forms a seamless, waterproof membrane that bonds directly to the roof’s surface.

Why Liquid Plastic Roofing?

- Seamless Protection: Unlike traditional roofing materials, which come in sheets or shingles, liquid plastic roofing forms a single layer that eliminates weak spots.

- Adaptable to Complex Roof Designs: Ideal for roofs with irregular shapes, protrusions, or varying slopes, liquid plastic conforms to the contours of your roof for consistent coverage.

- Durability: This roofing solution withstands UV exposure, extreme temperatures, and heavy rain, providing years of reliable protection.

Key Benefits of Liquid Plastic Roofing

Liquid plastic roofing offers a range of advantages, making it one of the best options for flat and complex roofing needs. Here are some of the standout benefits:

Waterproof and Weather-Resistant: Liquid plastic roofing creates a watertight seal that protects your property from leaks and water damage. It also withstands the harsh effects of sun exposure, cold, and other weather extremes.

Low Maintenance: Once installed, liquid plastic roofs require minimal maintenance, helping property owners save on long-term upkeep costs.

Fast Application: Liquid plastic roofing can be applied quickly, reducing disruption to your property or business. For commercial buildings, it can often be applied with minimal impact on operations.

Versatile Application: This roofing type can be used on a range of surfaces, including metal, wood, concrete, and asphalt, making it an ideal solution for various roofing types.

Sustainable: Liquid plastic roofing is often recyclable, making it an environmentally friendly choice. Additionally, its energy efficiency and potential for reduced maintenance contribute to a lower environmental footprint.

Step-by-Step Liquid Plastic Roofing Installation

At Surrey Roofing Specialists, we follow a precise process to ensure each liquid plastic roof is expertly installed. Here’s a breakdown of each stage of the installation process:

Step 1: Roof Inspection and Preparation

Before applying liquid plastic, it’s crucial to inspect the roof to ensure it’s ready for the coating process.

- Initial Roof Inspection: We start by assessing the roof’s current condition. Any damaged areas are repaired, and any signs of mould, debris, or old sealants are removed.

- Cleaning the Surface: The roof surface must be clean and free from dust, debris, or loose material. We thoroughly clean the roof to ensure that the liquid plastic bonds well with the underlying surface.

- Drying the Roof: If there’s been recent rainfall or cleaning, we ensure the roof is completely dry before moving on. Liquid plastic requires a dry surface for optimal adhesion.

Step 2: Priming the Roof

A primer is essential for ensuring strong adhesion between the roof surface and the liquid plastic layer.

- Applying the Primer: We apply a compatible primer to the entire roof surface, using a brush or roller for even coverage. The primer helps the liquid plastic coating stick better, ensuring maximum durability.

- Curing the Primer: The primer is allowed to cure for a specified period, usually several hours, to ensure it’s fully dry and ready for the liquid plastic application.

Step 3: Applying the Liquid Plastic Coating

Once the primer has cured, we proceed with applying the first layer of liquid plastic.

- Preparing the Coating: We mix the liquid plastic components as per manufacturer guidelines, ensuring a uniform blend for consistent application.

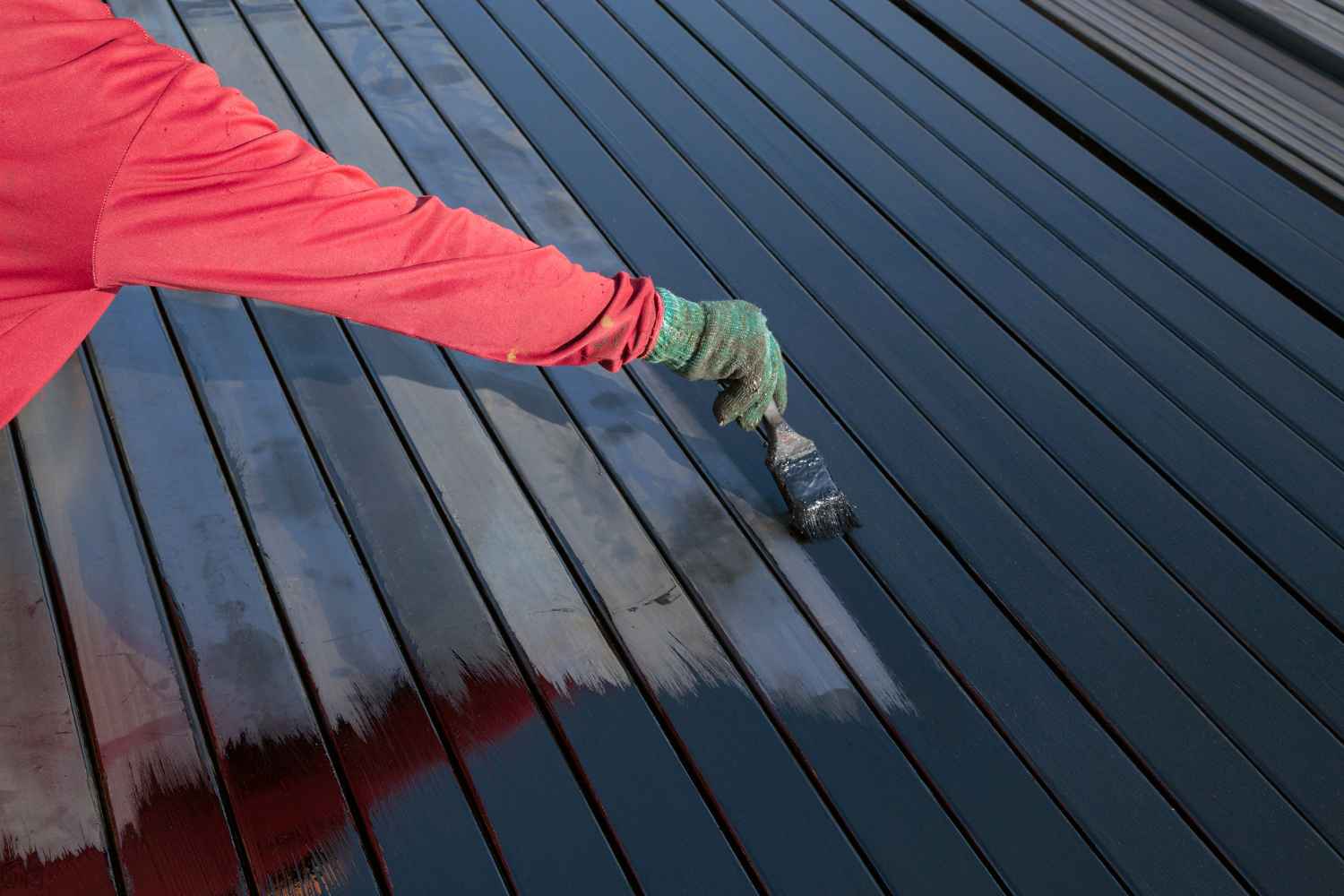

- Applying the First Layer: The liquid plastic is then spread over the entire roof surface using a roller or brush. We pay special attention to areas around vents, edges, and any other features that may need extra coverage.

- Allowing the First Layer to Cure: Once the initial layer is applied, we allow it to cure. This can take several hours, depending on weather conditions and product specifications.

Step 4: Reinforcing and Applying the Final Coat

To create a durable finish, we apply additional layers and reinforce key areas.

- Adding a Reinforcement Mesh: For extra durability, we place a reinforcing mesh over critical areas, such as joints, seams, and corners. This mesh helps the liquid plastic resist movement and temperature-related expansion and contraction.

- Applying the Final Coat: We then apply a second layer of liquid plastic over the entire roof, embedding the reinforcement mesh. This final coat provides a tough, seamless finish that offers excellent waterproofing and weather resistance.

Step 5: Curing and Final Inspection

Curing is essential for liquid plastic roofing to reach its full strength and durability.

- Curing Time: We allow the roof to cure for a recommended period, often up to 48 hours, to ensure it’s fully bonded and watertight.

- Final Inspection: Once the roof has cured, we conduct a thorough inspection to confirm the coating is even, and all areas are properly sealed.

Why Choose Surrey Roofing Specialists for Liquid Plastic Roofing?

Surrey Roofing Specialists has built a reputation for quality and expertise, making us a trusted choice for liquid plastic roofing across the UK. Here’s why clients prefer our services:

Proven Expertise: With years of experience in liquid plastic roofing, our team brings knowledge and skill to every project, ensuring reliable and durable results.

High-Quality Materials: We use only top-grade materials and coatings for our liquid plastic roofs, ensuring long-lasting performance and protection for your property.

Customer Satisfaction: From consultation to final inspection, we prioritize client satisfaction, working closely to meet your roofing needs and preferences.

Environmentally Conscious: We make sustainable choices wherever possible, selecting materials and processes that reduce environmental impact.

Applications of Liquid Plastic Roofing

Liquid plastic roofing is suitable for various types of roofs, particularly those with complex shapes or surfaces that require extra waterproofing.

Flat Roofs: Liquid plastic roofing is ideal for flat roofs as it provides seamless waterproofing.

Complex Roofs with Many Features: Roofs with vents, skylights, or unique shapes benefit from liquid plastic’s adaptability and easy application.

Balconies and Walkways: In addition to roofing, liquid plastic is a great solution for waterproofing balconies and walkways, providing slip resistance and durability.

Conclusion

Liquid plastic roofing is an excellent choice for UK property owners seeking a reliable, flexible, and waterproof roofing solution. At Surrey Roofing Specialists, we pride ourselves on delivering high-quality installations tailored to each client’s needs. With our attention to detail, use of top-grade materials, and commitment to lasting results, we ensure each liquid plastic roofing project stands up to the demands of UK weather.

If you’re interested in learning more about liquid plastic roofing or are ready to schedule an installation, contact Surrey Roofing Specialists today. Let us help you protect your property with a roofing solution that offers exceptional durability and performance.